The smooth operation of industrial systems depends on regular maintenance of the equipment used.

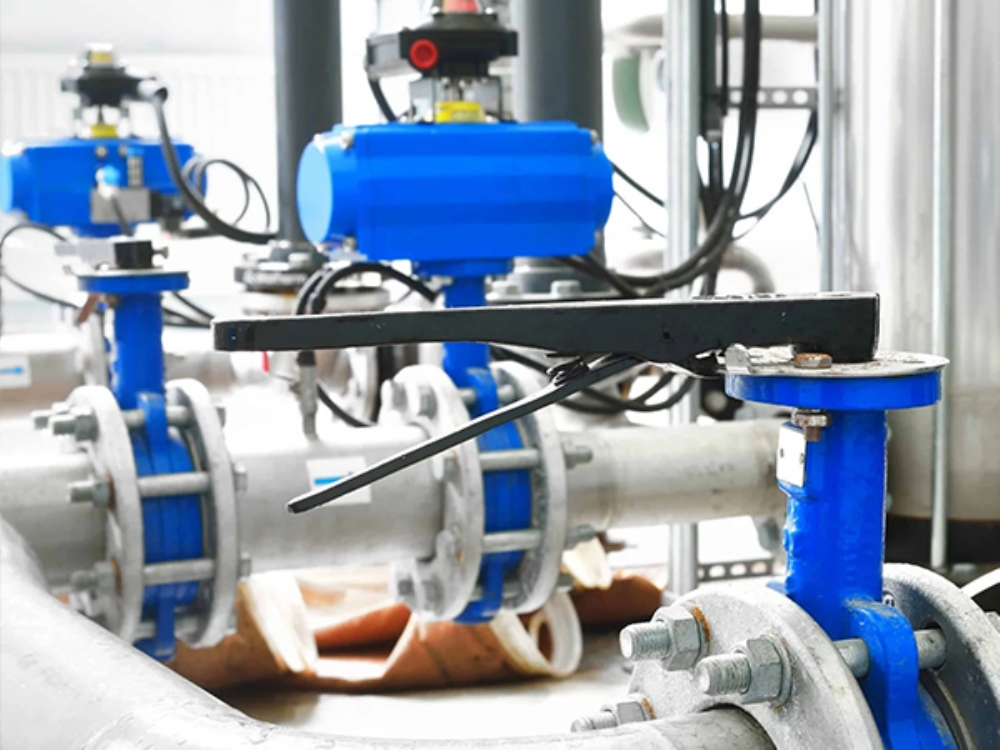

Valves operate under challenging conditions such as high temperatures, pressure, and chemical exposure. Regular maintenance is critical to preserving performance and ensuring system efficiency. Neglecting maintenance processes can lead to leaks, failures, and high costs. Here are key tips for valve maintenance and extending their lifespan:

Maintenance Tips

- Visual Inspection: Regularly check for leaks, corrosion, or deformation.

- Cleaning: Remove dirt and debris to ensure smooth valve operation.

- Sealing Components: Inspect gaskets and seals for wear and replace them if necessary.

- Lubrication: Regularly lubricate moving parts with appropriate lubricants.

- Testing and Calibration: Periodically test valve open-close functions and precision.

Tips to Extend Lifespan

- Proper Valve Selection: Choose valves suitable for the application and fluid.

- Appropriate Usage: Avoid over-stressing valves or excessively tightening them.

- Scheduled Maintenance Plan: Schedule maintenance tasks at regular intervals to prevent system downtime.

At Tegravalf, our expert team is here to help you maximize the performance and lifespan of your valves!